10 March 2025

Retail Lighting Revolutionised

The Impact of Additive Manufacturing on Retail Lighting

25 July 2024

Experiencing firsthand where other lighting suppliers had fallen short on customer service, Shoplight’s co-founders Mark and Mel Shortland spotted an opportunity to start their own business and fill a gap in the market. After working in the retail lighting industry for 14 years, Mark wanted to create a company that prioritised customer service and built long-term partnerships. In 2014, Shoplight Ltd was born.

Starting at the kitchen table, as many small businesses do, our first official premises were a shared friend’s warehouse – an office and three bays of racking for our first items of stock. Mark began to build a customer base while running the day-to-day operations, and Mel supported the business by taking on ‘back office’ duties whilst working elsewhere.

In those early days, the two most urgent challenges were acquiring a product supplier and onboarding customers. After impressing the Managing Director of a well-established European supplier, Mark gained the much-needed product range to build our product offer for UK retailers.

Establishing a great reputation and gaining the trust of customers can be difficult for new businesses. Prospective customers often see small startups as a potential risk, but throughout his sales career, Mark has built a personable and reliable standing with the people around him. After just six weeks, we secured our first customer when Skechers contacted Mark, as their incumbent supplier had let them down. After fulfilling that first job to an excellent standard, Skechers remains one of our biggest customers today.

Six months in, Shoplight expanded to premises at 10 Phorpres Close, Cygnet Park, a 1200-square-foot warehouse. In February 2015, Mel Shortland left her job and took a permanent operations role, and her father, Chris Crofts joined to manage the day-to-day warehouse operations. This freed Mark to focus on sales and the additional support helped add Moss Bros and Mountain Warehouse to our customer roster, both of whom remain loyal to the business 10 years on.

That warehouse was quickly pushed to its limits, advancing the need to expand into an adjoining unit, where the stock was stored for a one-million-pound refit programme for Waterstones in 2019.

As many small businesses can relate, the two biggest challenges the company faced during more recent years were Brexit and COVID-19. The aftermath of the decision to leave the EU left Mel and Mark worrying about how changes in legislation would affect the business. Fortunately, nothing changed surrounding imports and exports for three years; meaning they had time to learn and adapt. The decision to leave the EU would later give the company a competitive advantage as the business took the decision to support exports by becoming VAT-registered in the Netherlands, a key factor when Claire’s Accessories chose Shoplight to undertake a £2.2M refit programme in 2022-23.

In October 2019, Shoplight moved into newly designed offices and a bigger warehouse space at Unit 5, Titan Drive. In March 2020 COVID-19 struck the world.

Construction projects halted, and no goods were dispatched between March and May 2020. This period took a heavy toll on Mark and Mel, whose daily walks were filled with discussion about the impact COVID-19 could have on the company whilst weighing up possible outcomes.

Relative good news helped, as ‘lockdown’ happened at different times across European countries, it was found that we could still dispatch products to those countries that remained ‘open’ throughout the pandemic. Despite a 45% drop in revenue that year, the business survived, no redundancies were made and some months later, a large proportion of the furlough support used by the business was repaid to the UK government.

Due to the impact of COVID-19, it seemed that many competitors moved their focus away from retail and onto other sectors. Shoplight made the decision to remain dedicated to the retail market, recognising that people will always want human interaction through shopping and dining experiences.

Many business owners who survived the pandemic, wanted to improve and develop their business to come back stronger, Mark included. He undertook a week-long business course to dig deep into how the company’s strategy could be improved. A key outcome was to rebrand the business, creating a more modern and fresher look.

Alongside the new brand identity, a 12-month process began to become B Corp Certified. Shoplight already shared many values of the B Corp movement, so the decision to undertake the impact assessment and the subsequent certification process was relatively simple. After formalising several existing processes and making some changes, we joined the ranks of other certified purpose-driven businesses in the UK.

More recently, the focus has been on bringing in the right skillsets to take the business forward. The shift into manufacturing has demanded new people with specific skills and introducing the board of directors has contributed to business security. Ensuring a well-rounded team with different skills helps to ensure the company is positioned to thrive and grow beyond our first 10 years.

With sustainability being a key commitment, the move away from importing products was the obvious next step for Shoplight. Knowing there had to be a better way to manufacture in the UK, we turned our attention to producing our own retail lighting range through innovative materials and on-demand manufacturing, all delivered with 3D printers.

The impact the retail lighting industry has on carbon emissions and environmental waste is substantial. According to the International Aluminium Institute (IAI), Aluminium production generates around 1.1 billion tonnes of CO2 each year *. Mark believed that retailers opted for standard imported aluminium lighting due to a lack of availability of sustainable alternatives and it was this growing awareness of the problem, and a desire to move into more sustainable practices that drove the team to explore what to do next.

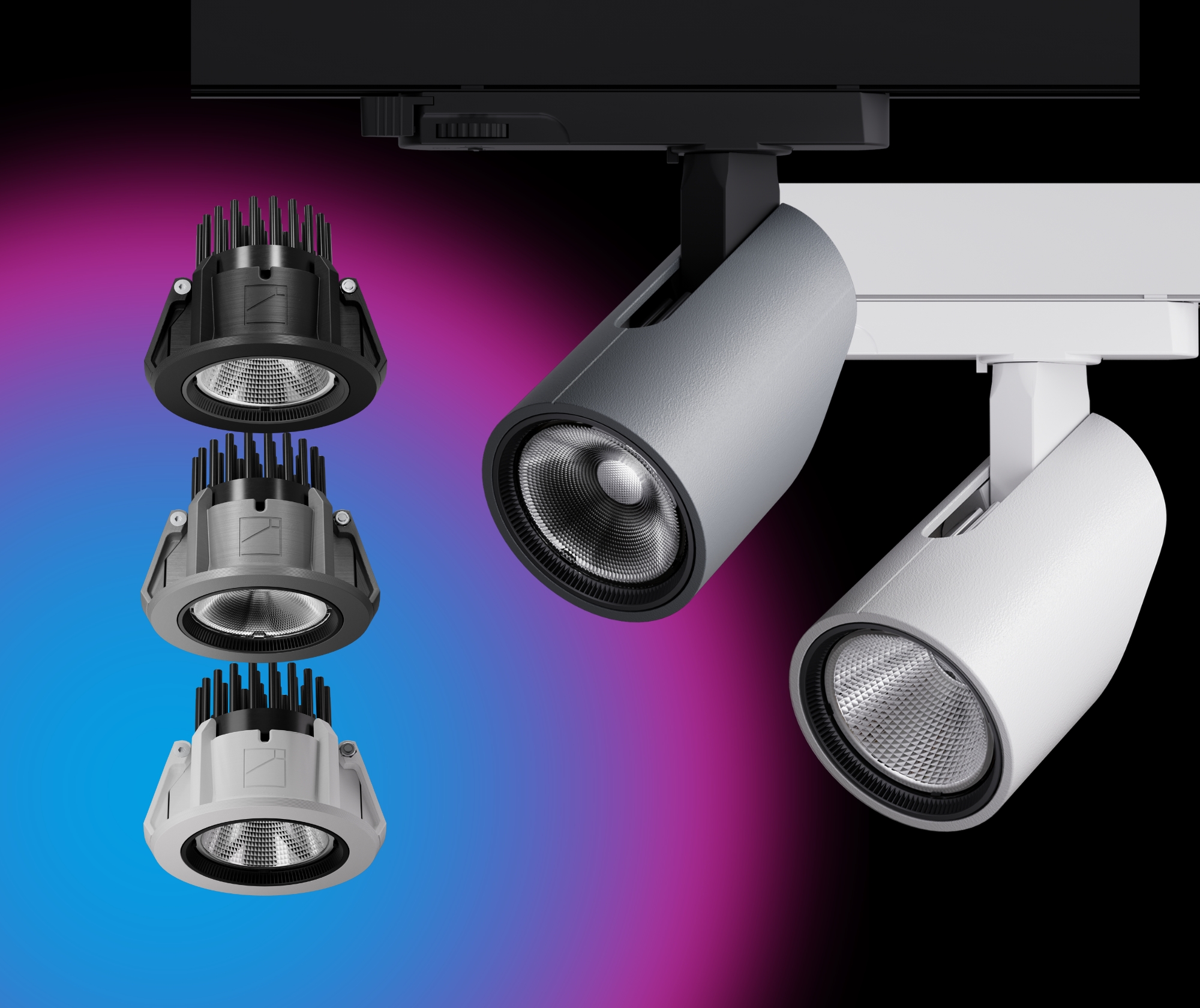

Further research brought James Bryden, a pioneering product designer, to the attention of Mark. Faced with a design challenge, James crafted prototypes over 9 months which evolved into Shoplight’s first biopolymer lighting solution – the innovative track-mounted spotlight, NORT. It incorporated a biopolymer frame which housed a uniquely designed aluminium heat sink and our patent pending VenTEC® technology. James succeeded in creating a viable design for NORT and this collaboration created a revolutionary product that challenges retail lighting industry norms.

Like Mark, James was also concerned about tackling the impact and waste retail luminaires had on landfills. In 2023, research found that approximately 19 million LED, solar and decorative lights ended up in UK landfill waste. ** This was a key factor contributing to the modular design approach found within our biopolymer range. James meticulously designed the products to have components that could easily be removed, replaced, and upgraded, right down to removing the need for thermal paste on the LED chips – and adopting a bayonet-style LED lamp holder.

Since launching our first biopolymer product, NORT, the range has grown to five, with each product offering a unique proposition – from track spotlights to fixed and adjustable recessed spotlights, and on to pendants.

After years of growth and the requirement for more space to house our new manufacturing needs, earlier this year Shoplight leased the adjoining building, expanding to a 10,000-square-foot operation. The manufacturing unit currently houses 65 3D printers (with the capacity for three times this number) and a new team that provides the resources to improve workflow, triple productivity and assemble hundreds of biopolymer products a week.

We are on track to produce 30,000 biopolymer products this year, and our target to reach 80% biopolymer in sales volume by 2028 is becoming a reality. Up next is the expansion of the biopolymer range with the introduction of two new products later this year together with pro-lenses which will provide the ability to achieve higher optical control compared to standard reflectors.

We continue to develop our site and will soon launch our new test lab complete with a goniometer, allowing us to undertake photometric testing in-house, improving our efficiencies and products further.

As Shoplight continues to grow, plans to drive innovation and focus on sustainability through further developments in 3D printing remain fundamental to our future. We are excited to see what the Shoplight team can achieve together and the impact we can have on cleaning up retail lighting, today and in the future.

**Source: Recolight, Oct 2023

10 March 2025

The Impact of Additive Manufacturing on Retail Lighting

31 January 2025

From Battlefields to Peaks:

27 January 2025

From University to Innovation:

24 January 2025

Compact Design, Big Impact.

24 October 2024

Shop Stories - From Vouchers to Variety